Startseite | Mitarbeiter | Forschung | Lehre | Veranstaltungen | Anfahrt | Intranet

Deutsch | English

Startseite | Mitarbeiter | Forschung | Lehre | Veranstaltungen | Anfahrt | Intranet

Deutsch | English

A recent approach to chemical vapor deposition (CVD) of thin metal films is based on pulsed spray evaporation (PSE) delivery of commercially available metalorganic precursors, in particular acetylacetonates. With these, alcohols may be used as both, solvent and reducing agent, admitting deposition of metal without using H2 for precursor reduction. To unambiguously characterize film quality and optimize process parameters, surface science analysis tools in ultrahigh vacuum (UHV) and contamination-free sample transfer from the CVD reactor at low vacuum into the UHV chamber are indispensable.

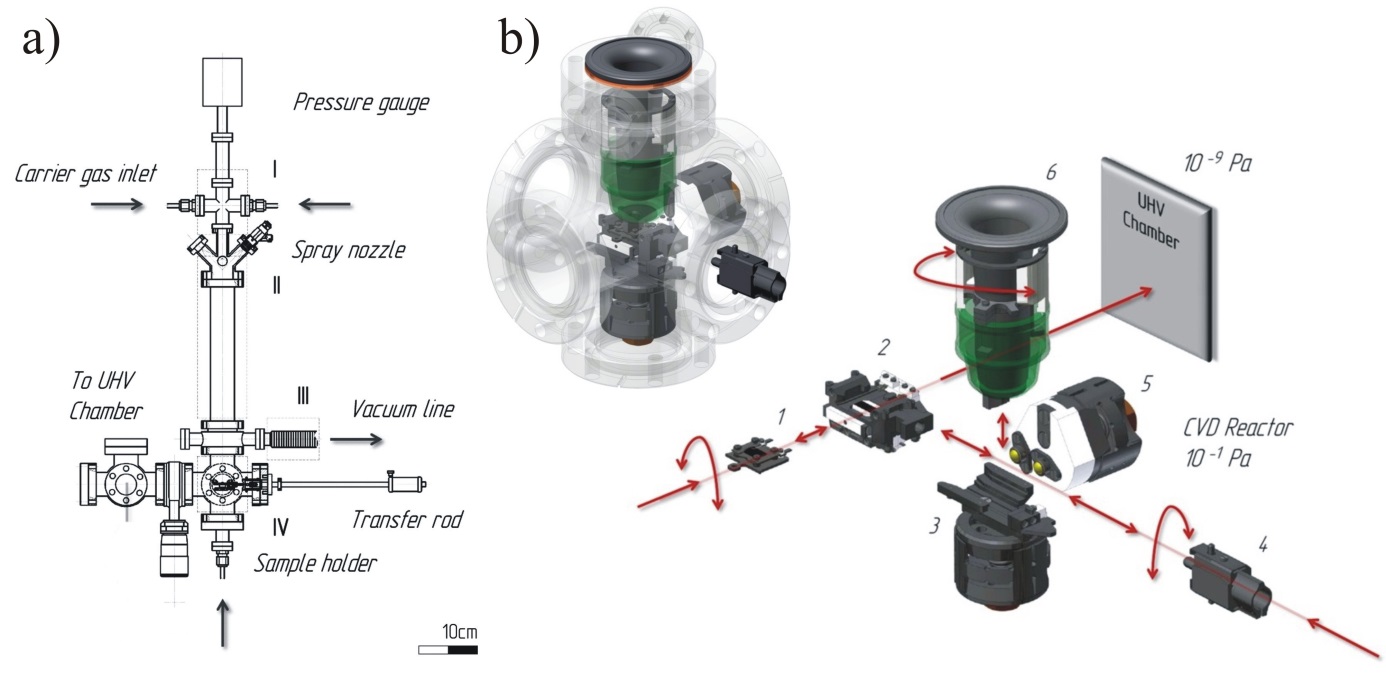

a) Drawing to scale of the novel UHV-compatible PSE-CVD reactor. b) Centerpiece of its design: all parts for sample manipulation and transfer (1-5) and shutter (6) fit into Conflat 38 six-ways cross (center: fully assembled, right: components’ degrees of freedom).

a) Drawing to scale of the novel UHV-compatible PSE-CVD reactor. b) Centerpiece of its design: all parts for sample manipulation and transfer (1-5) and shutter (6) fit into Conflat 38 six-ways cross (center: fully assembled, right: components’ degrees of freedom).

We have built a very compact PSE-CVD reactor for direct attachment to a commercial UHV system (Omicron Multiprobe). A uniquely designed shutter within the reactor avoids any contamination of sample holder, heater or transfer mechanism by precursor spray during deposition but allows for quick and easy sample transfer afterwards without compromising UHV conditions. Thereby, sample holder, heater and transfer mechanism fit into a Conflat 38 six-ways cross, resulting in a very compact setup which is based on many commercially available components and easily adaptable to other UHV systems. Last but not least, the reactor design is multifunctional: easy to use in thermal CVD or Atomic Layer Deposition regimes as well. First systematic studies on the influence of temperature on the kinetics of Ni film growth by PSE-CVD from Ni(acac)2 dissolved in ethanol have demonstrated the device capabilities.

Theodor Weiss, Martin Nowak, Volkmar Zielasek

References:

Cooperation partner: K. Kohse-Höinghaus, Fakultät für Chemie, Universität Bielefeld

Funding: DFG

For detailed information contact Volkmar Zielasek